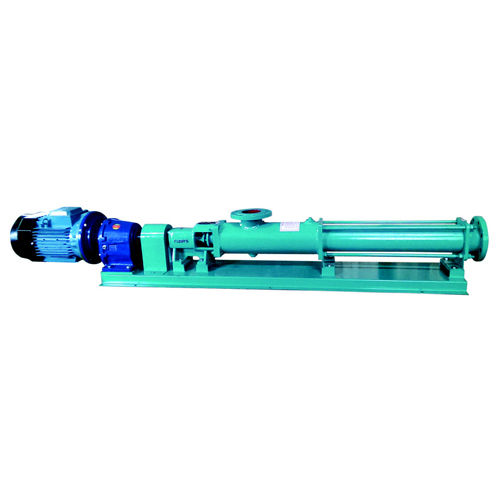

Progressive Cavity Pumps

Progressive Cavity Pumps Specification

- Mounting Type

- Baseplate Mounted

- Speed

- 1440 RPM

- Caliber

- 25 to 150 mm

- Inlet/Outlet

- 25 mm to 150 mm

- Frequency

- 50 Hz

- Head Size

- up to 48 bar

- Working Temperature

- Up to 120C

- Theory

- Progressive Cavity

- Voltage

- 415 V AC

- Discharge Pressure

- Up to 48 bar

- Noise Level

- Low

- Flow Rate

- up to 50 m/hr

- Max Suction

- 8 metres

- Control System

- Manual/Auto

- Features

- Non-clogging, gentle handling of media, reversible operation

- Material

- Cast Iron, Stainless Steel, Alloy Steel

- Structure

- Single Screw Pump

- Power

- 0.5 HP to 40 HP

- Standard

- API, ISO, DIN

- Fuel Type

- Electric

- Pressure

- Up to 48 bar

- Usage

- Industrial, Chemical, Wastewater, Food, Pharma

- Application

- Slurry, viscous liquids, chemicals, sludge transfer

- Suction Type

- Positive Displacement

- Seals Type

- Mechanical Seal / Gland Packing

- Priming

- Self-priming

- Pump Type

- Progressive Cavity Pump

- Capacity

- up to 50 m/hr

- Direction of Rotation

- Clockwise/Anti-clockwise

- Coupling

- Flexible/Pin Bush

- Lubrication

- Grease/Oil Lubricated Bearing Block

- Cooling Method

- Air-cooled

- Drive Type

- Motor/Belt Driven

- Stator Material

- Nitrile Rubber, EPDM, Viton

- Shaft Sleeve

- Hardened/Stainless Steel

- Rotor Material

- Hard Chrome Plated Steel

- Painting/Coating

- Epoxy coated for corrosion resistance

- Max Solid Handling

- up to 6 mm

Progressive Cavity Pumps Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit at Sight (Sight L/C)

- Main Domestic Market

- All India

About Progressive Cavity Pumps

Application Areas and Sites for Progressive Cavity Pumps

Progressive Cavity Pumps are designed for a myriad of applications, including chemical processing, wastewater treatment, food and pharmaceutical manufacturing, and industrial slurry or sludge transfer. Their celebrated non-clogging design supports use in challenging settings such as chemical plants, food processing units, and municipal wastewater installations. Operators can confidently employ these pumps on surfaces requiring gentle yet efficient fluid handlingensuring smooth flow of viscous or abrasive materials at any site demanding consistent, reliable performance.

Packaging, Drop-off, and Payment Details for Pumps

Each Progressive Cavity Pump is shipped with robust protective packaging to ensure secure drop-off at your designated site. Expenditure is made straightforward with flexible payment terms tailored to suit various procurement strategies. For quality assurance, sample units are available upon request, allowing for inspection and evaluation prior to full-scale investment. Our logistics support guarantees prompt delivery, while comprehensive documentation accompanies every shipment for seamless installation and commissioning.

FAQs of Progressive Cavity Pumps:

Q: How does the Progressive Cavity Pump handle viscous or solid-laden fluids?

A: The pumps celebrated single screw design, combined with a flexible stator, ensures gentle, non-clogging operation. This allows it to manage viscous liquids, slurries, and materials containing solids up to 6 mm efficiently.Q: What are the primary benefits of using hard chrome-plated steel rotors and epoxy coating?

A: Hard chrome-plated steel rotors provide durability, wear resistance, and extended pump life. The epoxy coating offers enhanced corrosion resistance, making the pumps valorous performers in demanding and corrosive environments.Q: Where can Progressive Cavity Pumps be installed for optimal performance?

A: These pumps are ace performers in industrial settings, chemical and wastewater plants, food processing facilities, and pharmaceutical manufacture sitesanywhere smooth handling of abrasive or sensitive fluids is required.Q: What packaging and shipping options are available for these pumps?

A: Each unit is securely packed for safe drop-off and can be shipped across India or internationally. Detailed documentation is included to facilitate seamless site installation and commissioning.Q: How can I sample or order Progressive Cavity Pumps, and what are the payment terms?

A: Sample pumps are available for evaluation before committing to bulk orders. Flexible payment terms help manage expenditure, supporting both upfront and staggered payment arrangements to suit your procurement process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Progressive Cavity Pump Category

Fss Series Hygiene Sanitary Design Pumps

Max Suction : Varies based on model

Control System : Manual/Automatic

Application : Other, Hygienic and sanitary fluid transfer

Pump Type : Other, Sanitary Pump

Features : Hygienic design easy cleaning corrosionresistant

Theory : Other, Positive displacement

Fsp Series Industrial Pumps

Max Suction : High suction capability

Control System : Electric motor driven

Application : Other, Industrial fluid transfer

Pump Type : Other, Rotary pump

Features : Durable efficient minimal maintenance

Theory : Other, Positive displacement pump

Fsw Series Industrial Hopper Pump

Max Suction : 5 meters

Control System : Electric motor with integrated control panel

Application : Industrial processes involving viscous semisolid material handling, Other

Pump Type : Hopper pump, Other

Features : Robust design high efficiency easy maintenance

Theory : Other, Progressive cavity theory

Fsv Series Vertical Pumps

Max Suction : 8 meters

Control System : Automatic

Application : Industrial Water Transfer, Other

Pump Type : Vertical Pump, Other

Features : High Efficiency Compact Design

Theory : Centrifugal Pump

Send Inquiry

Send Inquiry